Omaa Metal Sources is ASME B16.5 Flange Face and Finish (FF / RF / RTJ) Flanges Exporters and Suppliers in the US, UK, South Africa, Saudi Arabia, Singapore, UAE, Oman, South Korea, Turkey, Bahrain, Malaysia, Philippines, Thailand, Norway, Indonesia, Iraq, Yemen, Bangladesh, Nigeria, Egypt, Peru, Ghana, Morocco, Etc.

Raised Face and Flat Face Flange Manufacturers and Suppliers in India, RF Flange, Flange Face Finish Types, Ring Joint(RTJ), Lap Joint, Tongue and Groove(T&G) Supplier

Flanges are used in piping systems to connect pipes, valves, pumps, and other equipment. There are several types of flanges based on their shape, size, and application. Flanges can also have different face types, which are the surfaces that come into contact with the gasket and the mating flange during assembly. Here are some common flange face types:

- Flat face (FF): The most basic flange face type is the flat face. It is a smooth, flat surface that provides a good sealing surface when used with a flat gasket. It is commonly used in low-pressure applications.

- Raised face (RF): The raised face flange has a small raised portion around the perimeter of the flange face. This raised portion provides a better sealing surface for the gasket and allows for easier alignment during assembly. Raised face flanges are commonly used in medium to high-pressure applications.

- Ring type joint (RTJ): The ring type joint flange has a groove cut into the face of the flange, which is used to hold a metallic gasket. The gasket is compressed between two RTJ flanges, creating a metal-to-metal seal. RTJ flanges are commonly used in high-pressure and high-temperature applications.

Raised Face and Flat Face Flanges in ASTM A105 RTJ Flange, Carbon Steel, Inconel Alloy 600, 800, Incoloy 825 Flanges, Titanium Flanges, EN 1092-2 PN16 FF Flanges Exporter, Sch 80 Schedule 40 Stainless Steel 304, 304L, 316, 316L, and 904L Flanges Face Types, Series A & B Flanges, DIN 86029 PN10 Flange, Nickel Alloy Flange, Alloy 20 Flange, SMO 254 Flange at the Lowest Prices.

Flange Face and Finish Flanges Specifications

Size Range

Nominal OD Sizes:

12-3/8 – 27-1/8 inches

Tube Sizes:

10 to 24 inches

Class / Pressure Rating

150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

Standards / Dimensions

ANSI/ASME B16.5, B16.47 Series A & B, B16.48, JIS B2220, BS 4504, BS 10, BS1560-3.1, EN-1092, DIN, AS, GOST, MSS SP-44, ISO 70051, API7S-15, API7S-43, API605, AWWA, DIN

Connection Type

Ring Joint Flange (RTJ), Flat Face Flange (FF), Raised Face Flange (RF), Male and Female Flange (M & F), Lap Joint Flange, Large and Small Tongue-and-Groove Flange (T & G)

Material Standards

ASTM A105, ASTM A350, ASTM A182, ASTM A216, ASTM A352, ASTM A217, ASTM A515, ASTM A516, ASTM A203, A204, ASTM A387, ASTM A240, ASTM A694 FF / RF / RTJ Flange

Flanges Face Types, Flange Face Finish Materials & Grades

| ASTM A182 Flange |

|---|

| Stainless Steel 304, 304L, 316, 316L, 316H, 316Ti, 310, 310S, 317, 317L, 321, 347, 347H, 904L, SMO 254/6Mo, Duplex Steel-S31803/S32205, Super Duplex-S32750/S32760 F51, F52, F53, F54, F55, F57, F59, F60, F61, Alloy Steel F1, F5, F9, F11, F12, F22, F91 |

| ASTM B564 Flange |

|---|

| Incoloy 800, 800H, 800HT, 825, 925, Inconel 600, 601, 625, 718, 783, 690, X750, Nickel 200, 201, 205, 205LC, Hastelloy C276, C22, C4, C2000, B2, B3, X, Monel 400, 500 |

| ASTM A105 / A105N / A350 LF2 / A694 Flange |

|---|

| Carbon Steel F52, F56, F60, F65, F70, F80 |

| ASTM B247 Flange |

|---|

| Aluminium 7075, 5086, 6082, 3003, 5083, 6061, 1100 |

| ASTM B61 / B62 / B151 / B152 Flange |

|---|

| Copper Nickel 90/10 (C70600 ), 70/30 (C71500), UNS C71640 |

| ASTM B381 Flange |

|---|

| Titanium Grade 1, Grade 2, Grade 3, Grade 4, Grade 5, Grade 6, Grade 7, Grade 9, Grade 12 |

Find the largest ready stock of Flange Faces Types – Flange Face flange -Raised Face / Full Face / RTJ Ring Joint (Facing Types) pipe flanges in Mumbai, India.

Flange Face Finish Types

Types of Flange Facing Finish

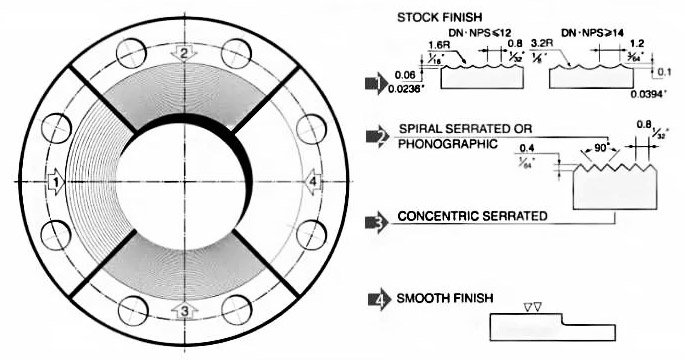

STOCK FINISH

It is the most widely used of any flange surface finish, because practically, is suitable for all ordinary service conditions. Under compression, the soft face from a gasket will embed into this finish, which helps create a seal, and a high level of friction is generated between the mating surfaces. The finish for these flanges is generated by a 1.6 mm radius round-nosed tool at a feed rate of 0.8 mm per revolution up to 12 inch. For sizes 14 inch and larger, the finish is made with 3.2 mm round-nosed tool at a feed of 1.2 mm per revolution.

SPIRAL SERRATED

This is also a continuous or phonographic spiral groove, but it differs from the stock finish in that the groove typically is generated using a 90-° tool which creates a “V” geometry with 45° angled serration.

CONCENTRIC SERRATED

As the name suggests, this finish is comprised of concentric grooves. A 90° tool is used and the serrations are spaced evenly across the face.

SMOOTH FINISH

This finish shows no visually apparent tool markings. These finishes are typically utilized for gaskets with metal facings such as double jacketed, flat steel and corrugated metal. The smooth surfaces mate to create a seal and depend on the flatness of the opposing faces to effect a seal. This is typically achieved by having the gasket contact surface formed by a continuous (sometimes called phonographic) spiral groove generated by a 0.8 mm radius round-nosed tool at a feed rate of 0.3 mm per revolution with a depth of 0.05 mm. This will result in a roughness between Ra 3.2 and 6.3 micrometers (125 – 250 micro inch).

Flange Face Types

Flange Face Types

RAISED FACE FLANGE (RF)

A raised face flange (RF) is easy to recognize as the gasket surface area is positioned above the bolting line of the flange. A raised face flange is compatible with a wide range of flange gaskets, ranging from flat to semi-metallic and metallic types (as, for example, jacketed gaskets and spiral wound gaskets), either ring or full face.

FLAT FACE FLANGE (FF)

Flat face flanges (FF) have a contact surface having the same height as the bolting line of the flange. Full face gaskets, generally of the soft type, are used between two flat face flanges. According to ASME B31.3, a flat face flange should never be mated with a raised face flange as the resulting flanged joint would definitely leak.

RING JOINT FLANGE (RTJ)

A ring joint flanges (RTJ) is used when a metal-to-metal seal between the mating flanges is required (which is a condition for high-pressure and high-temperature applications, i.e. above 700/800 C°). A ring joint flange features a circular groove to accommodate a ring joint gasket (oval, or rectangular). RTJ flanges can be sealed by RTJ gaskets of different styles (R, RX, BX) and profiles (example: octagonal/oval for the R style).

LAP JOINT FLANGE

A lap joint flange has a flat face, which is not used to seal the flanged joint but simply hosts the back of a stub end. The sealing surface is actually on the stub end itself and may be either flat face or raised face.

TONGUE AND GROOVE FLANGE (T AND G)

Two tongue and groove flanges (T&G face) perfectly fit one into the other: one flange has a raised ring, the other a groove and they can be mated easily (the tongue enters the groove and seals the joint).

MALE AND FEMALE FLANGE (M AND F)

Similarly to tongue and groove flanges, male and female flanges (M&F face type) match one to the other as well. One flange has an area extended beyond its face area, the male flange, the other flange has a matching depression machined on the facing surface, the female flange. The female face is 3/16” deep, while the male face is 1/4″ high, and both of them are smooth finished. The outer diameter of the female face retains the gasket.

Best quality Flange Face Finish Types includes Stock Finish, Spiral Serrated, Concentric Serrated, Smooth Finish Or Face, and Cold Water Finish, Flanges Face Types includes Raised Face(RF), Flat Face(FF), Ring Joint(RTJ), Lap Joint, Tongue and Groove(T&G), Male and Female(M&F) in Mumbai, India.

Flange Face and Finish Flange (FF / RF / RTJ) Applications

-

-

Petrochemical Industries

Petrochemical Industries

-

Pharmaceutical Equipment

Pharmaceutical Equipment

-

Power Generation

Power Generation

-

Heating Systems and Heat Exchanger

Heating Systems and Heat Exchanger

-

Pulp and Paper Industry

Pulp and Paper Industry

-

Mining Support

Mining Support

-

Chemical Equipment

Chemical Equipment

-

Gas Processing

Gas Processing

-

Plumbing

Plumbing

-

Nuclear Power Systems

Nuclear Power Systems

-

Condensers

Condensers

-

Sea Water Equipment

Sea Water Equipment

-

Buildings and Bridges

Buildings and Bridges

-

Industrial Water Lines

Industrial Water Lines

-

Food Processing Industry

Food Processing Industry

-

Fire Protection Systems

Fire Protection Systems

-

Off-Shore Oil Drilling Companies

Off-Shore Oil Drilling Companies

-

Australia, Afghanistan, Algeria, Angola, Argentina, Armenia, Azerbaijan, Bahrain, Bangladesh, Benin,

Bhutan, Botswana, Brazil, Brunei, Burkina Faso, Cambodia, Cameroon, Canada, Central Africa Republic,

Chad, Chile, Colombia, Cuba, Cyprus, DRC, Djibouti, Egypt, Equatorial Guinea, Eritrea, Eswatini,

Ethiopia, Fiji, Finland, France, Georgia, Germany, Ghana, Greece, Hungary, Iceland, Indonesia, Iran,

Iraq, Ireland, Israel, Italy, Japan, Jordan, Kazakhstan, Kenya, Kuwait, Kyrgyzstan, Laos, Lebanon,

Lesotho, Liberia, Libya, Lithuania, Madagascar, Malawi, Malaysia, Maldives, Mali, Mexico, Morocco,

Mozambique, Mauritania, Myanmar, Namibia, Nepal, Netherlands, New Zealand, Nigeria, Norway, Oman,

Panama, Peru, Philippines, Poland, Portugal, Palestine, Qatar, Russia, Rwanda, Romania, Saudi Arabia,

Senegal, Sierra Leone, Singapore, Slovakia, Somalia, South Africa, South Korea, South Sudan, Spain,

Sri Lanka, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Tasmania, Thailand, The Gambia,

Timor-Leste, Togo, Tunisia, Turkey, Turkiye, Turkmenistan, Uganda, Uzbekistan, United Arab Emirates (UAE),

United Kingdom (UK), United States (US), Venezuela, Vietnam, Yemen, Zambia, Zimbabwe

Abu Dhabi, Amsterdam, Abuja, Accra, Addis Ababa, Ahmedabad, Algiers, Amman, Ankara, Antananarivo,

Ashgabat, Asmara, Astana, Athens, Baghdad, Baku, Bamako, Bandar Seri Begawan, Bangkok, Bangui,

Banjul, Beirut, Bengaluru, Berlin, Bishkek, Bloemfontein, Bogotá, Bern, Brasília, Bratislava,

Bucharest, Budapest, Buenos Aires, Cairo, Canberra, Cape Town, Caracas, Chennai, Coimbatore, Dakar,

Damascus, Dhaka, Dili, Djibouti city, Dodoma, Doha, Dublin, Dushanbe, Freetown, Gaborone, Ghaziabad,

Guwahati, Hanoi, Harare, Havana, Helsinki, Hobart, Hyderabad, Indore, Jaipur, Jakarta, Jerusalem,

Juba, Jurong East, Kabul, Kampala, Kanpur, Kathmandu, Kigali, Kinshasa, Kochi, Kolkata, Kuala Lumpur,

Kuwait City, Lisbon, Lilongwe, Lima, Lobamba, Lomé, London, Luanda, Lucknow, Lusaka, Malabo, Madrid,

Malé, Mexico City, Manama, Moscow, Manila, Maputo, Maseru, Mbabane, Mogadishu, Monrovia, Mumabi,

Muscat, Nagpur, Nairobi, New Delhi, Niamey, Nicosia, Noida, Nouakchott, N’Djamena, Oslo, Ottawa,

Ouagadougou, Panama City, Paris, Patna, Phnom Penh, Porto-Novo, Pretoria, Pune, Rabat, Reykjavík,

Riyadh, Rome, Sana’a, Santiago, Sri Jayawardenepura Kotte, Stockholm, Seoul, Singapore, Surat,

Suva, Taipei City, Tashkent, Tokyo, Tbilisi, Tehran, Thimphu, Tripoli, Tunis, Vientiane, Vilnius,

Visakhapatnam, Warsaw, Washington D.C., Wellington, Windhoek, Yaoundé, Yerevan, Naypyidaw