Omaa Metal Sources is API 6A langes Exporters and Suppliers in the US, UK, South Africa, Saudi Arabia, Singapore, UAE, Oman, South Korea, Turkey, Bahrain, Malaysia, Philippines, Thailand, Norway, Indonesia, Iraq, Yemen, Bangladesh, Nigeria, Egypt, Peru, Ghana, Morocco, Etc.

API Flanges

API 6A Socket Weld Flanges, API 6BX Threaded Flanges, API weld neck Flange, API Plate Flange, API slip on Flanges Supplier, API Spectacle blind Flanges Manufacturer in India.

API flanges refer to flanges that meet the standards set by the American Petroleum Institute (API). These flanges are typically used in applications related to the oil and gas industry, including pipelines, refineries, and petrochemical plants.

API flanges come in various sizes and pressure ratings, and are available in different materials such as carbon steel, stainless steel, and alloy steel. The most commonly used API flanges are the API 6A and API 16A flanges.

API 6A flanges are used for wellhead and Christmas tree equipment, while API 16A flanges are used for blowout preventers (BOPs) and their associated equipment. These flanges are designed to withstand high pressure and temperature conditions, and are subject to rigorous testing and certification procedures to ensure their safety and reliability.

API flanges are typically connected using bolts and nuts, and the sealing surfaces are usually machined to ensure a tight and leak-free connection. Proper installation and maintenance of API flanges are crucial to ensure their performance and safety in high-pressure applications.

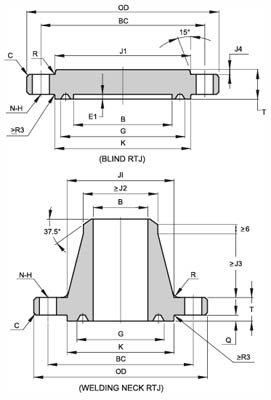

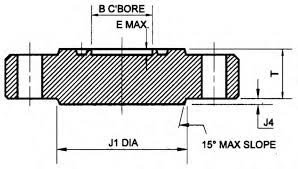

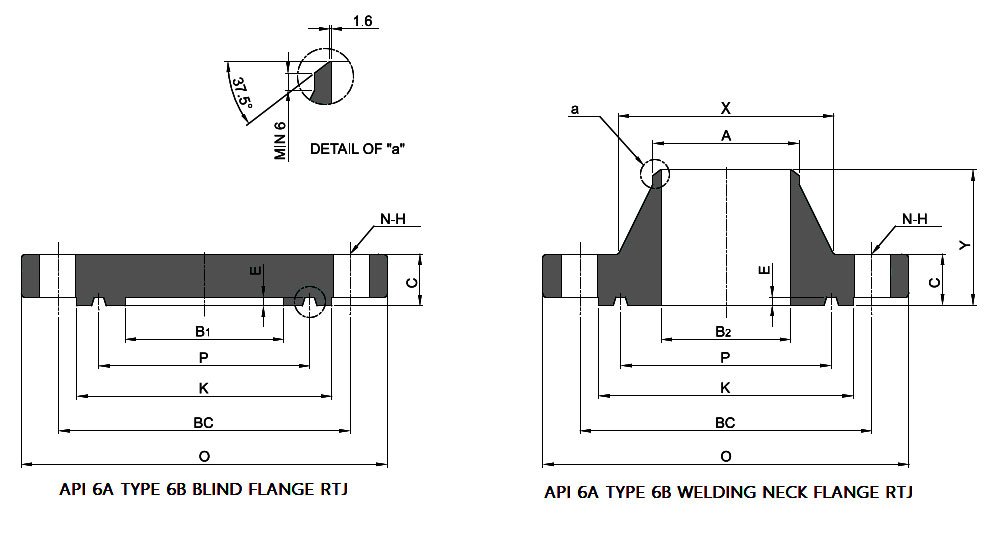

Ready Stock of API 6B Socket Weld Flange, Check Sizes And Dimensions Of API Forged Flanges, Suppliers of API Welding Neck Flange, API Ring Type Joint Orifice Flange, API 6A Blind Flanges.

API Flange Specifications

Size Range

1/2" (15 NB) to 48" (1200NB) DN10~DN5000

Class / Pressure Rating

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Standards / Dimensions

ANSI/ASME B16.5, B16.36, B16.48, BS4504, BS 10, EN-1092, DIN, BS, GOST, MSS SP-44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605

Connection Type

Ring Joint Flange (RTJ), Flat Face Flange (FF), Raised Face Flange (RF), Male and Female Flange (M & F), Lap Joint Flange, Large and Small Tongue-and-Groove Flange (T & G)

API Flanges Dimensions

| API 6A Type 6BX 15000PSI Blind / API 6A Welding Neck Flange Dimensions | API 6A Type 6B 2000PSI Welding Neck Flange Dimensions | API 6A Type 6BX 2000PSI Blind Flange Dimensions |

| API 6A Type 6B 3000PSI Blind / Welding Neck Flange Dimensions | API 6A 3000 Flange Dimensions | API 6A Type 6B 5000PSI Blind / Welding Neck Flange Dimensions |

| API 5000 Flange Dimensions | API 6A Type 6BX 10000PSI Blind / Welding Neck Flange Dimensions | MSS SP-44 API 6A Weld Neck / Blind / RTJ Flange Dimensions |

Size |

B |

OD |

C |

E1 |

Q |

G |

K |

T |

J1 |

J2 |

J3 |

J4 |

R |

BC |

N |

H |

Ring Number |

1 13/16" |

46.8 |

210 |

3 |

– |

5.56 |

77.77 |

106 |

45.3 |

97.6 |

71.4 |

47.6 |

– |

10 |

160.3 |

8 |

26 |

151 |

2 1/16" |

53.2 |

220 |

3 |

– |

5.95 |

86.23 |

114 |

50.8 |

111.1 |

82.5 |

54 |

– |

10 |

174.6 |

8 |

26 |

152 |

2 9/16" |

65.9 |

255 |

3 |

– |

6.75 |

102.77 |

133 |

57.2 |

128.6 |

100 |

57.1 |

– |

10 |

200 |

8 |

29 |

153 |

3 1/16" |

78.6 |

290 |

3 |

– |

7.54 |

119 |

154 |

64.3 |

154 |

122.2 |

63.5 |

– |

10 |

230.2 |

8 |

32 |

154 |

4 1/16" |

104 |

360 |

3 |

– |

8.33 |

150.62 |

194 |

78.6 |

195.3 |

158.7 |

73 |

– |

10 |

290.5 |

8 |

39 |

155 |

5 1/8" |

131 |

420 |

3 |

9.5 |

9.53 |

176.66 |

225 |

98.5 |

244.5 |

200 |

81.8 |

6.4 |

16 |

342.9 |

12 |

42 |

169 |

7 1/16" |

180.2 |

505 |

6 |

11.1 |

11.11 |

241.83 |

305 |

119.1 |

325.4 |

276.2 |

92.1 |

7.9 |

16 |

428.6 |

16 |

42 |

156 |

9 " |

229.4 |

650 |

6 |

12.7 |

12.7 |

299.06 |

381 |

146.1 |

431.8 |

349.2 |

123.8 |

14.2 |

16 |

552.4 |

16 |

51 |

157 |

11" |

280.2 |

815 |

6 |

14.3 |

14.29 |

357.23 |

454 |

187.4 |

584.2 |

427 |

235.7 |

12.7 |

16 |

711.2 |

20 |

54 |

158 |

13 5/8" |

346.9 |

885 |

6 |

15.9 |

15.88 |

432.64 |

541 |

204.8 |

595.3 |

528.6 |

114.3 |

17.5 |

25 |

771.5 |

20 |

61 |

159 |

18 3/4" |

477 |

1160 |

6 |

18.3 |

18.26 |

577.9 |

722 |

255.6 |

812.8 |

730.2 |

155.6 |

35.1 |

25 |

1016 |

20 |

80 |

164 |

1. RING NUMBER BX, 2. C should be the max value 3. Tolerance and Ring Gasket according to API 6A-20TH

Size |

B |

OD |

C |

K |

P |

E |

T |

Q |

X |

BC |

N |

H |

LN |

HL |

JL |

R/RX |

2 1/16" |

53.2 |

165 |

3 |

108 |

82.55 |

7.9 |

33.4 |

25.4 |

84 |

127 |

8 |

20 |

81 |

60.3 |

53.3 |

23 |

2 9/16" |

65.9 |

190 |

3 |

127 |

101.6 |

7.9 |

36.6 |

28.6 |

100 |

149.2 |

8 |

23 |

88 |

73 |

63.5 |

26 |

3 1/8" |

81.8 |

210 |

3 |

146 |

123.83 |

7.9 |

39.7 |

31.8 |

117 |

168.3 |

8 |

23 |

91 |

88.9 |

78.7 |

31 |

4 1/16" |

108.7 |

275 |

3 |

175 |

149.23 |

7.9 |

46.1 |

38.1 |

152 |

215.9 |

8 |

26 |

110 |

114.3 |

103.1 |

37 |

5 1/8" |

131 |

330 |

3 |

210 |

180.98 |

7.9 |

52.4 |

44.5 |

189 |

266.7 |

8 |

29 |

122 |

141.3 |

122.9 |

41 |

7 1/16" |

181.8 |

355 |

6 |

241 |

211.15 |

7.9 |

55.6 |

47.6 |

222 |

292.1 |

12 |

29 |

126 |

168.3 |

147.1 |

45 |

9" |

229.4 |

420 |

6 |

302 |

269.88 |

7.9 |

63.5 |

55.6 |

273 |

349.3 |

12 |

32 |

141 |

219.1 |

199.1 |

49 |

11" |

280.2 |

510 |

6 |

356 |

323.85 |

7.9 |

71.5 |

63.5 |

343 |

431.8 |

16 |

35 |

160 |

273 |

248.4 |

53 |

13 5/8" |

346.9 |

560 |

6 |

413 |

381 |

7.9 |

74.7 |

66.7 |

400 |

489 |

20 |

35 |

– |

– |

– |

57 |

16 3/4" |

426.2 |

685 |

6 |

508 |

469.9 |

7.9 |

84.2 |

76.2 |

495 |

603.2 |

20 |

42 |

– |

– |

– |

65 |

21 1/4" |

540.5 |

815 |

6 |

635 |

584.2 |

9.7 |

98.5 |

88.9 |

610 |

723.9 |

24 |

45 |

– |

– |

– |

73 |

Size |

OD |

C |

E1 |

G |

K |

T |

J1 |

J4 |

R |

BC |

N |

H |

BX |

26 3/4" |

1040 |

6 |

21.4 |

768.33 |

805 |

126.3 |

835.8 |

9.7 |

16 |

952.5 |

20 |

48 |

167 |

30" |

1120 |

6 |

23 |

862.3 |

908 |

134.2 |

931.9 |

17.5 |

16 |

1039.8 |

32 |

45 |

303 |

Size |

B |

OD |

C |

K |

P |

E |

T |

Q |

X |

BC |

N |

H |

LN |

HL |

JL |

R/RX |

2 1/16" |

53.2 |

215 |

3 |

124 |

95.25 |

7.9 |

46.1 |

38.1 |

104.8 |

165.1 |

8 |

26 |

109.6 |

60.3 |

50 |

24 |

2 9/16" |

65.9 |

245 |

3 |

137 |

107.95 |

7.9 |

49.3 |

41.3 |

123.8 |

190.5 |

8 |

29 |

112.7 |

73 |

59.7 |

27 |

3 1/8" |

81.8 |

240 |

3 |

156 |

123.83 |

7.9 |

46.1 |

38.1 |

127 |

190.5 |

8 |

26 |

109.5 |

88.9 |

74.4 |

31 |

4 1/16" |

108.7 |

290 |

3 |

181 |

149.23 |

7.9 |

52.4 |

44.4 |

158.8 |

235 |

8 |

32 |

122.2 |

114.3 |

98 |

37 |

5 1/8" |

131 |

350 |

3 |

216 |

180.98 |

7.9 |

58.8 |

50.8 |

190.5 |

279.4 |

8 |

35 |

134.9 |

141.3 |

122.9 |

41 |

7 1/16" |

181.8 |

380 |

6 |

241 |

211.15 |

7.9 |

63.5 |

55.6 |

235 |

317.5 |

12 |

32 |

147.6 |

168.3 |

147.1 |

45 |

9" |

229.4 |

470 |

6 |

308 |

269.88 |

7.9 |

71.5 |

63.5 |

298.5 |

393.7 |

12 |

39 |

169.9 |

219.1 |

189.7 |

49 |

11" |

280.2 |

545 |

6 |

362 |

323.85 |

7.9 |

77.8 |

69.9 |

368.3 |

469.9 |

16 |

39 |

192.1 |

273 |

237.2 |

53 |

13 5/8" |

346.9 |

610 |

6 |

419 |

381 |

7.9 |

87.4 |

79.4 |

419.1 |

533.4 |

20 |

39 |

– |

– |

– |

57 |

16 3/4" |

426.2 |

705 |

6 |

524 |

469.9 |

11.2 |

100.1 |

88.9 |

508 |

616 |

20 |

45 |

– |

– |

– |

66 |

20 3/4" |

527.8 |

855 |

6 |

648 |

584.2 |

12.7 |

120.7 |

108 |

622.3 |

749.3 |

20 |

54 |

– |

– |

– |

74 |

Find the largest ready stock of API 6A Flanges, API Flange Price List, API Slip On Flanges Dealer, API 6BX Reducing Flanges Stockist, Check Availability of API Threaded Flanges, API 6B RF Flanges Supplier, API Forged Flanges in Mumbai, India.

| Size | B | OD | C | K | P | E | T | Q | X | BC | N | H | LN | HL | JL | R/RX |

| 2 1/16" | 53.2 | 215 | 3 | 124 | 95.25 | 7.9 | 46.1 | 38.1 | 104.8 | 165.1 | 8 | 26 | 109.6 | 60.3 | 50 | 24 |

| 2 9/16" | 65.9 | 245 | 3 | 137 | 107.95 | 7.9 | 49.3 | 41.3 | 123.8 | 190.5 | 8 | 29 | 112.7 | 73 | 59.7 | 27 |

| 3 1/8" | 81.8 | 240 | 3 | 156 | 123.83 | 7.9 | 46.1 | 38.1 | 127 | 190.5 | 8 | 26 | 109.5 | 88.9 | 74.4 | 31 |

| 4 1/16" | 108.7 | 290 | 3 | 181 | 149.23 | 7.9 | 52.4 | 44.4 | 158.8 | 235 | 8 | 32 | 122.2 | 114.3 | 98 | 37 |

| 5 1/8" | 131 | 350 | 3 | 216 | 180.98 | 7.9 | 58.8 | 50.8 | 190.5 | 279.4 | 8 | 35 | 134.9 | 141.3 | 122.9 | 41 |

| 7 1/16" | 181.8 | 380 | 6 | 241 | 211.15 | 7.9 | 63.5 | 55.6 | 235 | 317.5 | 12 | 32 | 147.6 | 168.3 | 147.1 | 45 |

| 9" | 229.4 | 470 | 6 | 308 | 269.88 | 7.9 | 71.5 | 63.5 | 298.5 | 393.7 | 12 | 39 | 169.9 | 219.1 | 189.7 | 49 |

| 11" | 280.2 | 545 | 6 | 362 | 323.85 | 7.9 | 77.8 | 69.9 | 368.3 | 469.9 | 16 | 39 | 192.1 | 273 | 237.2 | 53 |

| 13 5/8" | 346.9 | 610 | 6 | 419 | 381 | 7.9 | 87.4 | 79.4 | 419.1 | 533.4 | 20 | 39 | – | – | – | 57 |

| 16 3/4" | 426.2 | 705 | 6 | 524 | 469.9 | 11.2 | 100.1 | 88.9 | 508 | 616 | 20 | 45 | – | – | – | 66 |

| 20 3/4" | 527.8 | 855 | 6 | 648 | 584.2 | 12.7 | 120.7 | 108 | 622.3 | 749.3 | 20 | 54 | – | – | – | 74 |

Size |

B |

OD |

C |

K |

P |

E |

T |

Q |

X |

BC |

N |

H |

LN |

HL |

JL |

R/RX |

2 1/16" |

53.2 |

215 |

3 |

124 |

95.25 |

7.9 |

46.1 |

38.1 |

104.8 |

165.1 |

8 |

26 |

109.5 |

60.3 |

43.7 |

24 |

2 9/16" |

65.9 |

245 |

3 |

137 |

107.95 |

7.9 |

49.3 |

41.3 |

123.8 |

190.5 |

8 |

29 |

112.7 |

73 |

54.9 |

27 |

3 1/8" |

81.8 |

265 |

3 |

168 |

136.53 |

7.9 |

55.6 |

47.7 |

133.3 |

203.2 |

8 |

32 |

125.4 |

88.9 |

67.5 |

35 |

4 1/16" |

108.7 |

310 |

3 |

194 |

161.93 |

7.9 |

62 |

54 |

161.9 |

241.3 |

8 |

35 |

131.8 |

114.3 |

88.1 |

39 |

5 1/8" |

131 |

375 |

3 |

229 |

193.68 |

7.9 |

81 |

73.1 |

196.8 |

292.1 |

8 |

42 |

163.5 |

141.3 |

110.3 |

44 |

7 1/16" |

181.8 |

395 |

6 |

248 |

211.15 |

9.7 |

92.1 |

82.6 |

228.6 |

317.5 |

12 |

39 |

181 |

168.3 |

132.6 |

46 |

9" |

229.4 |

485 |

6 |

318 |

269.88 |

11.2 |

103.2 |

92.1 |

292.1 |

393.7 |

12 |

45 |

223.8 |

219.1 |

173.8 |

50 |

11" |

280.2 |

585 |

6 |

371 |

323.85 |

11.2 |

119.1 |

108 |

368.3 |

482.6 |

12 |

51 |

265.1 |

273.1 |

216.7 |

54 |

| Size | B | OD | C | K | P | E | T | Q | X | BC | N | H | LN | HL | JL | R/RX |

| 2 1/16" | 53.2 | 215 | 3 | 124 | 95.25 | 7.9 | 46.1 | 38.1 | 104.8 | 165.1 | 8 | 26 | 109.5 | 60.3 | 43.7 | 24 |

| 2 9/16" | 65.9 | 245 | 3 | 137 | 107.95 | 7.9 | 49.3 | 41.3 | 123.8 | 190.5 | 8 | 29 | 112.7 | 73 | 54.9 | 27 |

| 3 1/8" | 81.8 | 265 | 3 | 168 | 136.53 | 7.9 | 55.6 | 47.7 | 133.3 | 203.2 | 8 | 32 | 125.4 | 88.9 | 67.5 | 35 |

| 4 1/16" | 108.7 | 310 | 3 | 194 | 161.93 | 7.9 | 62 | 54 | 161.9 | 241.3 | 8 | 35 | 131.8 | 114.3 | 88.1 | 39 |

| 5 1/8" | 131 | 375 | 3 | 229 | 193.68 | 7.9 | 81 | 73.1 | 196.8 | 292.1 | 8 | 42 | 163.5 | 141.3 | 110.3 | 44 |

| 7 1/16" | 181.8 | 395 | 6 | 248 | 211.15 | 9.7 | 92.1 | 82.6 | 228.6 | 317.5 | 12 | 39 | 181 | 168.3 | 132.6 | 46 |

| 9" | 229.4 | 485 | 6 | 318 | 269.88 | 11.2 | 103.2 | 92.1 | 292.1 | 393.7 | 12 | 45 | 223.8 | 219.1 | 173.8 | 50 |

| 11" | 280.2 | 585 | 6 | 371 | 323.85 | 11.2 | 119.1 | 108 | 368.3 | 482.6 | 12 | 51 | 265.1 | 273.1 | 216.7 | 54 |

| Size | B | OD | C | E1 | Q | G | K | T | J1 | J2 | J3 | J4 | R | BC | N | H | BX |

| 1 13/16" | 46.8 | 185 | 3 | – | 5.56 | 77.77 | 105 | 42.1 | 88.9 | 65.1 | 48.5 | – | 10 | 146.1 | 8 | 23 | 151 |

| 2 1/16" | 53.2 | 200 | 3 | – | 5.95 | 86.23 | 111 | 44.1 | 100 | 74.7 | 51.6 | – | 10 | 158.8 | 8 | 23 | 152 |

| 2 9/16" | 65.9 | 230 | 3 | – | 6.75 | 102.77 | 132 | 51.2 | 120.7 | 92.1 | 57.2 | – | 10 | 184.2 | 8 | 26 | 153 |

| 3 1/16" | 78.6 | 270 | 3 | – | 7.54 | 119 | 152 | 58.4 | 142.1 | 110.2 | 63.5 | – | 10 | 215.9 | 8 | 29 | 154 |

| 4 1/16" | 104 | 315 | 3 | – | 8.33 | 150.62 | 185 | 70.3 | 182.6 | 146.1 | 73.1 | – | 10 | 258.8 | 8 | 32 | 155 |

| 5 1/8" | 131 | 360 | 3 | 9.5 | 9.53 | 176.66 | 221 | 79.4 | 223.8 | 182.6 | 81 | 6.4 | 10 | 300 | 12 | 32 | 169 |

| 7 1/16" | 180.2 | 480 | 6 | 11.1 | 11.11 | 241.83 | 302 | 103.2 | 301.6 | 254 | 95.3 | 9.7 | 16 | 403.2 | 12 | 42 | 156 |

| 9 " | 229.4 | 550 | 6 | 12.7 | 12.7 | 299.06 | 359 | 123.9 | 374.7 | 327.1 | 93.7 | 9.7 | 16 | 476.3 | 16 | 42 | 157 |

| 11" | 280.2 | 655 | 6 | 14.3 | 14.29 | 357.23 | 429 | 141.3 | 450.9 | 400.1 | 103.2 | 14.2 | 16 | 565.2 | 16 | 48 | 158 |

| 13 5/8" | 346.9 | 770 | 6 | 15.9 | 15.88 | 432.64 | 518 | 168.3 | 552.5 | 495.3 | 114.3 | 17.5 | 16 | 673.1 | 20 | 51 | 159 |

| 16 3/4" | 426.2 | 870 | 6 | 8.3 | 8.33 | 478.33 | 576 | 168.3 | 655.6 | 601.7 | 76.2 | 30.2 | 19 | 776.3 | 24 | 51 | 162 |

| 18 3/4" | 477 | 1040 | 6 | 18.3 | 18.26 | 577.9 | 697 | 223.1 | 752.5 | 674.7 | 155.6 | 25.4 | 16 | 925.5 | 24 | 61 | 164 |

| 21 1/4" | 540.5 | 1145 | 6 | 19.1 | 19.05 | 647.88 | 781 | 241.3 | 847.7 | 762 | 165.1 | 31.8 | 21 | 1022.4 | 24 | 67 | 166 |

Size |

B |

OD |

C |

E1 |

Q |

G |

K |

T |

J1 |

J2 |

J3 |

J4 |

R |

BC |

N |

H |

BX |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1 13/16″ |

46.8 |

185 |

3 |

– |

5.56 |

77.77 |

105 |

42.1 |

88.9 |

65.1 |

48.5 |

– |

10 |

146.1 |

8 |

23 |

151 |

2 1/16″ |

53.2 |

200 |

3 |

– |

5.95 |

86.23 |

111 |

44.1 |

100 |

74.7 |

51.6 |

– |

10 |

158.8 |

8 |

23 |

152 |

2 9/16″ |

65.9 |

230 |

3 |

– |

6.75 |

102.77 |

132 |

51.2 |

120.7 |

92.1 |

57.2 |

– |

10 |

184.2 |

8 |

26 |

153 |

3 1/16″ |

78.6 |

270 |

3 |

– |

7.54 |

119 |

152 |

58.4 |

142.1 |

110.2 |

63.5 |

– |

10 |

215.9 |

8 |

29 |

154 |

4 1/16″ |

104 |

315 |

3 |

– |

8.33 |

150.62 |

185 |

70.3 |

182.6 |

146.1 |

73.1 |

– |

10 |

258.8 |

8 |

32 |

155 |

5 1/8″ |

131 |

360 |

3 |

9.5 |

9.53 |

176.66 |

221 |

79.4 |

223.8 |

182.6 |

81 |

6.4 |

10 |

300 |

12 |

32 |

169 |

7 1/16″ |

180.2 |

480 |

6 |

11.1 |

11.11 |

241.83 |

302 |

103.2 |

301.6 |

254 |

95.3 |

9.7 |

16 |

403.2 |

12 |

42 |

156 |

9 “ |

229.4 |

550 |

6 |

12.7 |

12.7 |

299.06 |

359 |

123.9 |

374.7 |

327.1 |

93.7 |

9.7 |

16 |

476.3 |

16 |

42 |

157 |

11″ |

280.2 |

655 |

6 |

14.3 |

14.29 |

357.23 |

429 |

141.3 |

450.9 |

400.1 |

103.2 |

14.2 |

16 |

565.2 |

16 |

48 |

158 |

13 5/8″ |

346.9 |

770 |

6 |

15.9 |

15.88 |

432.64 |

518 |

168.3 |

552.5 |

495.3 |

114.3 |

17.5 |

16 |

673.1 |

20 |

51 |

159 |

16 3/4″ |

426.2 |

870 |

6 |

8.3 |

8.33 |

478.33 |

576 |

168.3 |

655.6 |

601.7 |

76.2 |

30.2 |

19 |

776.3 |

24 |

51 |

162 |

18 3/4″ |

477 |

1040 |

6 |

18.3 |

18.26 |

577.9 |

697 |

223.1 |

752.5 |

674.7 |

155.6 |

25.4 |

16 |

925.5 |

24 |

61 |

164 |

21 1/4″ |

540.5 |

1145 |

6 |

19.1 |

19.05 |

647.88 |

781 |

241.3 |

847.7 |

762 |

165.1 |

31.8 |

21 |

1022.4 |

24 |

67 |

166 |

API 6A Flanges Tolerance

| Nominal Size Of Bore | Bore (Maximam) | Outside Diameter (O.D.) | Dimensional Tolerance | Maximam Chamfer |

| B | D | D | C | |

| 2000 PSI | ||||

| 26¾ | 26.78 | 41 | ± 0.12 | 0.25 |

| 30 | 30.03 | 44.19 | ± 0.12 | 0.25 |

| 3000 PSI | ||||

| 26¾ | 26.78 | 43.38 | ± 0.12 | 0.25 |

| 30 | 30.03 | 46.68 | ± 0.12 | 0.25 |

| 5000 PSI | ||||

| 13.3/8 | 13.66 | 26.5 | ± 0.12 | 0.25 |

| 16¾ | 16.78 | 30.38 | ± 0.12 | 0.25 |

| 18¾ | 18.78 | 35.62 | ± 0.12 | 0.25 |

| 21¾ | 21.28 | 39 | ± 0.12 | 0.25 |

| 10000 PSI | ||||

| 1.13/16 | 1.84 | 7.38 | ± 0.06 | 0.12 |

| 2.1/16 | 2.09 | 7.88 | ± 0.06 | 0.12 |

| 2.9/16 | 2.59 | 9.12 | ± 0.06 | 0.12 |

| 3.1/16 | 3.09 | 10.62 | ± 0.06 | 0.12 |

| 4.1/16 | 4.09 | 12.44 | ± 0.06 | 0.12 |

| 5.1/8 | 5.16 | 14.06 | ± 0.06 | 0.12 |

| 7.1/16 | 7.09 | 18.88 | ± 0.12 | 0.25 |

| 9 | 9.03 | 21.75 | ± 0.12 | 0.25 |

| 11 | 11.03 | 25.75 | ± 0.12 | 0.25 |

| 13.5/8 | 13.66 | 30.25 | ± 0.12 | 0.25 |

| 16¾ | 16.78 | 34.31 | ± 0.12 | 0.25 |

| 18¾ | 18.78 | 40.94 | ± 0.12 | 0.25 |

| 21¼ | 21.28 | 45 | ± 0.12 | 0.25 |

| 15000 PSI | ||||

| 1.13/16 | 1.84 | 8.19 | ± 0.06 | 0.12 |

| 2.1/16 | 2.09 | 8.75 | ± 0.06 | 0.12 |

| 2.9/16 | 2.59 | 10 | ± 0.06 | 0.12 |

| 3.1/16 | 3.09 | 11.31 | ± 0.06 | 0.12 |

| 4.1/16 | 4.09 | 14.19 | ± 0.06 | 0.12 |

| 5.1/8 | 5.16 | 16.5 | ± 0.06 | 0.12 |

| 7.1/16 | 7.09 | 19.88 | ± 0.12 | 0.25 |

| 9 | 9.03 | 25.5 | ± 0.12 | 0.25 |

| 11 | 11.03 | 32 | ± 0.12 | 0.25 |

| 13.5/8 | 13.66 | 34.88 | ± 0.12 | 0.25 |

| 18¾ | 18.78 | 45.75 | ± 0.12 | 0.25 |

| 20000 PSI | ||||

| 1.13/16 | 1.84 | 10.12 | ± 0.06 | 0.12 |

| 2.1/16 | 2.09 | 11.31 | ± 0.06 | 0.12 |

| 2.9/16 | 2.59 | 12.81 | ± 0.06 | 0.12 |

| 3.1/16 | 3.09 | 14.06 | ± 0.06 | 0.12 |

| 4.1/16 | 4.09 | 17.56 | ± 0.06 | 0.12 |

| 7.1/16 | 7.09 | 25.81 | ± 0.12 | 0.25 |

| 9 | 9.03 | 31.69 | ± 0.12 | 0.25 |

| 11 | 11.03 | 34.75 | ± 0.12 | 0.25 |

| 13.5/8 | 13.66 | 45.75 | ± 0.12 | 0.25 |

| Nominal Size and Bore |

Dia Raised Face |

Total THK |

Large Dia Hub |

Small Dia Hub |

| F | T | A | E | |

| 2000 PSI | ||||

| 26¾ | 31.69 | 4.97 | 32.91 | 29.25 |

| 30 | 35.75 | 5.28 | 36.69 | 32.8 |

| 3000 PSI | ||||

| 26¾ | 32.75 | 6.34 | 34.25 | 30.56 |

| 30 | 36.31 | 6.58 | 38.19 | 34.3 |

| 5000 PSI | ||||

| 13.3/8 | 18 | 4.44 | 18.94 | 16.69 |

| 16¾ | 21.06 | 5.13 | 21.88 | 20.75 |

| 18¾ | 24.69 | 6.53 | 26.56 | 23.56 |

| 21¾ | 27.62 | 7.12 | 29.88 | 26.75 |

| 10000 PSI | ||||

| 1.13/16 | 4.12 | 1.66 | 3.5 | 2.56 |

| 2.1/16 | 4.38 | 1.73 | 3.94 | 2.94 |

| 2.9/16 | 5.19 | 2.02 | 4.75 | 3.62 |

| 3.1/16 | 6 | 2.3 | 5.59 | 4.34 |

| 4.1/16 | 7.28 | 2.77 | 7.19 | 5.75 |

| 5.1/8 | 8.69 | 3.12 | 8.81 | 7.19 |

| 7.1/16 | 11.88 | 4.06 | 11.88 | 10 |

| 9 | 14.12 | 4.88 | 14.75 | 12.88 |

| 11 | 16.88 | 5.56 | 17.75 | 15.75 |

| 13.5/8 | 20.38 | 6.62 | 21.75 | 19.5 |

| 16¾ | 22.69 | 6.62 | 25.81 | 23.69 |

| 18¾ | 27.44 | 8.78 | 29.62 | 26.56 |

| 21¼ | 30.75 | 9.5 | 33.38 | 30 |

| 15000 PSI | ||||

| 1.13/16 | 4.19 | 1.78 | 3.84 | 2.81 |

| 2.1/16 | 4.5 | 2 | 4.38 | 3.25 |

| 2.9/16 | 5.25 | 2.25 | 5.06 | 3.94 |

| 3.1/16 | 6.06 | 2.53 | 6.06 | 4.81 |

| 4.1/16 | 7.62 | 3.09 | 7.69 | 6.25 |

| 5.1/8 | 8.88 | 3.88 | 9.62 | 7.88 |

| 7.1/16 | 12 | 4.6 | 12.81 | 10.88 |

| 9 | 15 | 5.75 | 17 | 13.75 |

| 11 | 17.88 | 7.38 | 23 | 16.81 |

| 13.5/8 | 21.31 | 8.06 | 23.44 | 20.81 |

| 18¾ | 28.44 | 10.06 | 32 | 28.75 |

| 20000 PSI | ||||

| 1.13/16 | 4.62 | 2.5 | 5.25 | 4.31 |

| 2.1/16 | 5.19 | 2.81 | 6.06 | 5 |

| 2.9/16 | 5.94 | 3.12 | 6.81 | 5.69 |

| 3.1/16 | 6.75 | 3.38 | 7.56 | 6.31 |

| 4.1/16 | 8.62 | 4.19 | 9.56 | 8.12 |

| 7.1/16 | 13.88 | 6.5 | 15.19 | 13.31 |

| 9 | 17.38 | 8.06 | 18.94 | 16.88 |

| 11 | 19.88 | 8.81 | 22.31 | 20 |

| 13.5/8 | 24.19 | 11.5 | 27.31 | 24.75 |

API 6A Flanges Thickness

| NPS (Normal Pipe Size) | "A" (O.D.) Outside Daimeter |

"B" (Thick.) |

"C" (RF Daimeter) |

"D" (B.C.D.) |

# Bolt Holes |

Diameter of Bolt Holes |

Apprx. Weight In KG |

| 1/2" | 3-1/2 | 7/16 | 1-3/8 | 2-3/8 | 4 | 5/8 | 2 |

| 3/4" | 3-7/8 | 1/2 | 1-11/16 | 2-3/4 | 4 | 5/8 | 2 |

| 1" | 4-1/4 | 9/16 | 2 | 3-1/8 | 4 | 5/8 | 2 |

| 1-1/4" | 4-5/8 | 5/8 | 2-1/2 | 3-1/2 | 4 | 5/8 | 3 |

| 1-1/2" | 5 | 11/16 | 2-7/8 | 3-7/8 | 4 | 5/8 | 3 |

| 2" | 6 | 3/4 | 3-5/8 | 4-3/4 | 4 | 3/4 | 4 |

| 2-1/2" | 7 | 7/8 | 4-1/8 | 5-1/2 | 4 | 3/4 | 7 |

| 3" | 7-1/2 | 15/16 | 5 | 6 | 4 | 3/4 | 9 |

| 3-1/2" | 8-1/2 | 15/16 | 5-1/2 | 7 | 8 | 3/4 | 13 |

| 4" | 9 | 15/16 | 6-3/16 | 7-1/2 | 8 | 3/4 | 17 |

| 5" | 10 | 15/16 | 7-5/16 | 8-1/2 | 8 | 7/8 | 20 |

| 6" | 11 | 1 | 8-1/2 | 9-1/2 | 8 | 7/8 | 27 |

| 8" | 13-1/2 | 1-1/8 | 10-5/8 | 11-3/4 | 8 | 7/8 | 47 |

| 10" | 16 | 1-3/16 | 12-3/4 | 14-1/4 | 12 | 1 | 67 |

| 12" | 19 | 1-1/4 | 15 | 17 | 12 | 1 | 123 |

| 14" | 21 | 1-3/8 | 16-1/4 | 18-3/4 | 12 | 1-1/8 | 139 |

| 16" | 23-1/2 | 1-7/16 | 18-1/2 | 21-1/4 | 16 | 1-1/8 | 187 |

| 18" | 25 | 1-9/16 | 21 | 22-3/4 | 16 | 1-1/4 | 217 |

| 20" | 27-1/2 | 1-11/16 | 23 | 25 | 20 | 1-1/4 | 283 |

| 24" | 32 | 1-7/8 | 27-1/4 | 29-1/2 | 20 | 1-3/8 | 415 |

API Flanges Mechanical Properties

| Test Pressure | 3,000 PSI | 4,500 PSI | 7,500 PSI | 15,000 PSI | 22,500 PSI | 30,000 PSI |

|---|---|---|---|---|---|---|

| Maxi. Working Pressure | 2,000 PSI | 3,000 PSI | 5,000 PSI | 10,000 PSI | 15,000 PSI | 20,000 PSI |

| Temperature Rating | K (-60 Deg C) TO Y (+345 Deg C) | K (-60 Deg C) To Y (+345 Deg C) | K (-60 Deg C) To Y (+345 Deg C) | K (-60 Deg C) To Y (+345 Deg C) | K (-60 Deg C) To Y (+345 Deg C) | K (-60 Deg C) To Y (+345 Deg C) |

| Product Specification Levels | 1, 2, 3 & 4 | 1, 2, 3 & 4 | 1, 2, 3 & 4 | 1, 2, 3 & 4 | 1, 2, 3 & 4 | 1, 2, 3 & 4 |

API 6A Flanges Equivalent

| Weld Neck, Integral, Blinds, Equivalent | |||

| Maximam Working Pressure |

2000 PSI |

3000 PSI |

5000 PSI |

| Test Pressure | 3000 PSI | 4500 PSI | 7500 PSI |

| Product Spec Levels |

1, 2, 3 and 4 | 1, 2, 3 and 4 | 1, 2, 3 and 4 |

| API Temperature Rating |

K (-60 ° C) to Y (+345 ° C) |

K (-60 ° C) to Y (+345 ° C) |

K (-60 ° C) to Y (+345 ° C) |

| Integral, Blind, Target Blind and Test Flanges | |||

| Minimam Yield | 60 000 PSI | 60 000 PSI | 60 000 PSI |

| Minimam Tensile | 85 000 PSI | 85 000 PSI | 85 000 PSI |

| Material | API 60K | API 60K | API 60K |

API Flanges Pressure Ratings

Flange Size |

Working Pressure (PSI) |

Outside Diameter |

Number of Bolt Holes |

Diameter of Bolt Holes |

Length of Bolts |

API Ring Gasket |

|---|---|---|---|---|---|---|

1-13/16" |

10,000 |

7-3/8" |

8 |

3/4" |

5-1/4" |

BX-151 |

1-13/16" |

15,000 |

8-3/16" |

8 |

7/8" |

6" |

BX-151 |

1-13/16" |

20,000 |

10-1/8" |

8 |

1" |

7-3/4" |

BX-151 |

2-1/16" |

2,000 |

6-1/2" |

8 |

5/8" |

5/8" |

R-23 |

2-1/16" |

3,000/5,000 |

8-1/2" |

8 |

7/8" |

7/8" |

R-24 |

2-1/16" |

10,000 |

7-7/8" |

8 |

3/4" |

3/4" |

BX-152 |

2-1/16" |

15,000 |

8-3/4" |

8 |

7/8" |

7/8" |

BX-152 |

2-1/16" |

20,000 |

11-5/16" |

8 |

1-1/8" |

1-1/8" |

BX-152 |

2-9/16" |

2,000 |

7-1/2" |

8 |

3/4" |

5-1/4" |

R-26 |

2-9/16" |

3,000/5,000 |

9-5/8" |

8 |

1" |

7" |

R-27 |

2-9/16" |

10,000 |

9-1/8" |

8 |

7/8" |

6-1/4" |

BX-153 |

2-9/16" |

15,000 |

10" |

8 |

1" |

7" |

BX-153 |

2-9/16" |

20,000 |

12-13/16" |

8 |

1-1/4" |

9-1/2" |

BX-153 |

3-1/8" |

2,000 |

8-1/4" |

8 |

3/4" |

5-1/2" |

R-31 |

3-1/8" |

3,000 |

9-1/2" |

8 |

7/8" |

6-1/4" |

R-31 |

3-1/8" |

5,000 |

10-1/2" |

8 |

1-1/8" |

7-3/4" |

R-35 |

3-1/16" |

10,000 |

10-5/8" |

8 |

1" |

7-1/4" |

BX-154 |

3-1/16" |

15,000 |

11-5/16" |

8 |

1-1/8" |

8" |

BX-154 |

3-1/16" |

20,000 |

14-1/16" |

8 |

1-3/8" |

10-3/4" |

BX-154 |

4-1/16" |

2,000 |

10-3/4" |

8 |

7/8" |

6-1/4" |

R-37 |

4-1/16" |

3,000 |

11-1/2" |

8 |

1-1/8" |

7-1/2" |

R-37 |

4-1/16" |

5,000 |

12-1/4" |

8 |

1-1/8" |

8-3/8" |

BX-155 |

4-1/16" |

20,000 |

17-9/16" |

8 |

1-3/4" |

12-3/4" |

BX-155 |

5-1/8" |

5,000 |

14-3/4" |

8 |

1-1/2" |

10-3/4" |

R-44 |

7-1/16" |

2,000 |

14" |

12 |

1" |

7-1/2" |

R-45 |

7-1/16" |

3,000 |

15" |

12 |

1-1/8" |

8-1/2" |

R-45 |

7-1/16" |

5,000 |

15-1/2" |

12 |

1-3/8" |

11-1/4" |

R-46 |

7-1/16" |

10,000 |

18-7/8" |

12 |

1-1/2" |

11-3/4" |

BX-156 |

7-1/16" |

15,000 |

19-7/8" |

16 |

1-1/2" |

13" |

BX-156 |

7-1/16" |

20,000 |

24-13/16" |

16 |

2" |

17-3/4" |

BX-156 |

9" |

2,000 |

16-1/2" |

12 |

1-1/8" |

8-1/2" |

R-49 |

9" |

3,000 |

18-1/2" |

12 |

1-3/8" |

9-1/2" |

R-49 |

9" |

5,000" |

19" |

12 |

1-5/8" |

12-1/2" |

R-50 |

9" |

10,000 |

21-3/4" |

16 |

1-1/2" |

13-1/4" |

BX-157 |

9" |

15,000 |

25-1/2" |

16 |

1-7/8" |

16" |

BX-157 |

11" |

2,000 |

20" |

16 |

1-1/4" |

9-1/4" |

R-53 |

11" |

3,000 |

21-1/2" |

16 |

1-3/8" |

10" |

R-53 |

11" |

5,000 |

23" |

12 |

1-7/8" |

14-1/4" |

R-54 |

11" |

10,000 |

25-3/4" |

16 |

1-3/4" |

15-3/8" |

BX-158 |

11" |

15,000 |

32" |

20 |

2" |

19-1/2" |

BX-158 |

13-5/8" |

2,000 |

22" |

20 |

1-1/4" |

9-1/2" |

R-57 |

13-5/8" |

3,000 |

24" |

20 |

1-3/8" |

10-3/4" |

R-57 |

13-5/8" |

5,000 |

26-1/2" |

16 |

1-5/8" |

12-3/4" |

BX-160 |

13-5/8" |

10,000 |

30-1/4" |

20 |

1-7/8" |

17-3/4" |

BX-159 |

13-5/8" |

15,000 |

34-7/8" |

20 |

2-1/4" |

21" |

BX-159 |

16-3/4" |

2,000 |

27" |

20 |

1-1/2" |

10-3/4" |

R-65 |

16-3/4" |

3,000 |

27-3/4" |

20 |

1-5/8" |

12-1/4" |

R-66 |

16-3/4" |

5,000 |

30-3/8" |

16 |

1-78" |

14-3/4" |

BX-162 |

16-3/4" |

10,000 |

34-5/16" |

24 |

1-7/8" |

17-3/4" |

BX-162 |

18-3/4" |

5,000 |

35-5/8" |

20 |

2" |

18" |

BX-163 |

16-3/4" |

10,000 |

40-15/16" |

24 |

2-1/4" |

23" |

BX-164 |

20-3/4" |

3,000 |

33-3/4" |

20 |

2" |

15-1/4" |

R-74 |

21-1/4" |

2,000 |

32" |

24 |

1-5/8" |

12-1/2" |

R-73 |

21-1/4" |

5,000 |

39" |

24 |

2" |

19" |

BX-165 |

21-1/4" |

10,000 |

45" |

24 |

2-1/2" |

24-3/4" |

BX-166 |

26-3/4" |

2,000 |

41" |

20 |

1-3/4" |

14-1/4" |

BX-167 |

21-1/4" |

3,000 |

43-3/8" |

24 |

2" |

17-1/2" |

BX-168 |

API 6A Flanges Bolt And Ring Chart

API 6A Adapter Flanges Torque Values

API 6B Flanges Weight Chart

| NPS In Inch. | DN In MM | Flange Outside Daimeter A In MM | Flange Thickness D In MM | API 6a SORF Flange Weight In KG | API 6a WN Flange Weight In KG | API 6a BLRF Flange Weight In KG |

| 1/ 2 | 15 | 88.9 | 11.2 | 0.4 | 0.5 | 0.4 |

| 3/ 4 | 20 | 98.6 | 12.7 | 0.6 | 0.7 | 0.6 |

| 1 | 25 | 108 | 14.2 | 0.8 | 1 | 0.9 |

| 1 1/ 4 | 32 | 117.3 | 15.7 | 1 | 1.3 | 1.2 |

| 1 1/ 2 | 40 | 127 | 17.5 | 1.3 | 1.7 | 1.5 |

| 2 | 50 | 152.4 | 19.1 | 2.1 | 2.6 | 2.4 |

| 2 1/ 2 | 65 | 177.8 | 22.4 | 3.3 | 4.1 | 3.9 |

| 3 | 80 | 190.5 | 23.9 | 3.9 | 4.9 | 4.9 |

| 3 1/ 2 | 90 | 215.9 | 23.9 | 4.8 | 6.1 | 6.2 |

| 4 | 100 | 228.6 | 23.9 | 5.3 | 6.8 | 7.0 |

| 5 | 125 | 254 | 23.9 | 6.1 | 8.6 | 8.6 |

| 6 | 150 | 279.4 | 25.4 | 7.5 | 10.6 | 11.3 |

| 8 | 200 | 342.9 | 28.4 | 12.1 | 17.6 | 19.6 |

| 10 | 250 | 406.4 | 30.2 | 16.5 | 24 | 28.6 |

| 12 | 300 | 482.6 | 31.8 | 26.2 | 36.5 | 43.2 |

| 14 | 350 | 533.4 | 35.1 | 34.6 | 48.4 | 58.1 |

| 16 | 400 | 596.9 | 36.6 | 44.8 | 60.6 | 76.1 |

| 18 | 450 | 635 | 39.6 | 48.9 | 68.3 | 93.7 |

| 20 | 500 | 698.5 | 42.9 | 61.9 | 84.5 | 122.0 |

| 24 | 600 | 812.8 | 47.8 | 86.9 | 115 | 185.0 |

Best quality API Flanges, API Nipoflange, API Flanges Price, API 6B Groove Flange, API RTJ Flange, API Flanges Facing Type & Finish, API 6BX Weldoflange, API Square Flange, View Specification Of API Orifice Flange, API 6A langes Raised Face, API Expander Flanges at Best Price.

API Flanges Applications

-

-

Petrochemical Industries

Petrochemical Industries

-

Pharmaceutical Equipment

Pharmaceutical Equipment

-

Power Generation

Power Generation

-

Heating Systems and Heat Exchanger

Heating Systems and Heat Exchanger

-

Pulp and Paper Industry

Pulp and Paper Industry

-

Mining Support

Mining Support

-

Chemical Equipment

Chemical Equipment

-

Gas Processing

Gas Processing

-

Plumbing

Plumbing

-

Nuclear Power Systems

Nuclear Power Systems

-

Condensers

Condensers

-

Sea Water Equipment

Sea Water Equipment

-

Buildings and Bridges

Buildings and Bridges

-

Industrial Water Lines

Industrial Water Lines

-

Food Processing Industry

Food Processing Industry

-

Fire Protection Systems

Fire Protection Systems

-

Off-Shore Oil Drilling Companies

Off-Shore Oil Drilling Companies

-

Australia, Afghanistan, Algeria, Angola, Argentina, Armenia, Azerbaijan, Bahrain, Bangladesh, Benin,

Bhutan, Botswana, Brazil, Brunei, Burkina Faso, Cambodia, Cameroon, Canada, Central Africa Republic,

Chad, Chile, Colombia, Cuba, Cyprus, DRC, Djibouti, Egypt, Equatorial Guinea, Eritrea, Eswatini,

Ethiopia, Fiji, Finland, France, Georgia, Germany, Ghana, Greece, Hungary, Iceland, Indonesia, Iran,

Iraq, Ireland, Israel, Italy, Japan, Jordan, Kazakhstan, Kenya, Kuwait, Kyrgyzstan, Laos, Lebanon,

Lesotho, Liberia, Libya, Lithuania, Madagascar, Malawi, Malaysia, Maldives, Mali, Mexico, Morocco,

Mozambique, Mauritania, Myanmar, Namibia, Nepal, Netherlands, New Zealand, Nigeria, Norway, Oman,

Panama, Peru, Philippines, Poland, Portugal, Palestine, Qatar, Russia, Rwanda, Romania, Saudi Arabia,

Senegal, Sierra Leone, Singapore, Slovakia, Somalia, South Africa, South Korea, South Sudan, Spain,

Sri Lanka, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Tasmania, Thailand, The Gambia,

Timor-Leste, Togo, Tunisia, Turkey, Turkiye, Turkmenistan, Uganda, Uzbekistan, United Arab Emirates (UAE),

United Kingdom (UK), United States (US), Venezuela, Vietnam, Yemen, Zambia, Zimbabwe

Abu Dhabi, Amsterdam, Abuja, Accra, Addis Ababa, Ahmedabad, Algiers, Amman, Ankara, Antananarivo,

Ashgabat, Asmara, Astana, Athens, Baghdad, Baku, Bamako, Bandar Seri Begawan, Bangkok, Bangui,

Banjul, Beirut, Bengaluru, Berlin, Bishkek, Bloemfontein, Bogotá, Bern, Brasília, Bratislava,

Bucharest, Budapest, Buenos Aires, Cairo, Canberra, Cape Town, Caracas, Chennai, Coimbatore, Dakar,

Damascus, Dhaka, Dili, Djibouti city, Dodoma, Doha, Dublin, Dushanbe, Freetown, Gaborone, Ghaziabad,

Guwahati, Hanoi, Harare, Havana, Helsinki, Hobart, Hyderabad, Indore, Jaipur, Jakarta, Jerusalem,

Juba, Jurong East, Kabul, Kampala, Kanpur, Kathmandu, Kigali, Kinshasa, Kochi, Kolkata, Kuala Lumpur,

Kuwait City, Lisbon, Lilongwe, Lima, Lobamba, Lomé, London, Luanda, Lucknow, Lusaka, Malabo, Madrid,

Malé, Mexico City, Manama, Moscow, Manila, Maputo, Maseru, Mbabane, Mogadishu, Monrovia, Mumabi,

Muscat, Nagpur, Nairobi, New Delhi, Niamey, Nicosia, Noida, Nouakchott, N’Djamena, Oslo, Ottawa,

Ouagadougou, Panama City, Paris, Patna, Phnom Penh, Porto-Novo, Pretoria, Pune, Rabat, Reykjavík,

Riyadh, Rome, Sana’a, Santiago, Sri Jayawardenepura Kotte, Stockholm, Seoul, Singapore, Surat,

Suva, Taipei City, Tashkent, Tokyo, Tbilisi, Tehran, Thimphu, Tripoli, Tunis, Vientiane, Vilnius,

Visakhapatnam, Warsaw, Washington D.C., Wellington, Windhoek, Yaoundé, Yerevan, Naypyidaw