Flange Manufacturer & Supplier – All Type of Flange Solutions

Flanges play a critical role in industrial piping systems by providing a secure connection between pipes, valves, and other equipment. As a trusted flange manufacturer and supplier, we offer a comprehensive range of flange types to meet diverse industrial requirements. Whether it’s for high-pressure systems, small-diameter applications, or flow measurement, we provide the right flange solution to ensure durability, safety, and efficiency.

Below is an overview of the most common types of flanges used across industries:

Types of Flanges:

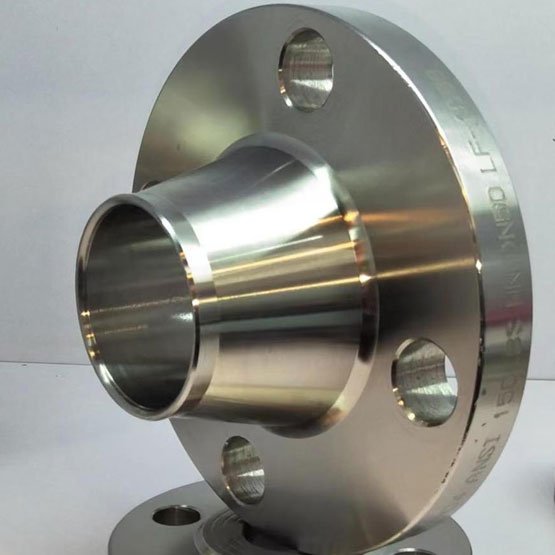

• Weld Neck Flanges (WNRF / WNFF): Weld neck flanges are designed to provide a smooth transition from the pipe to the flange, reducing stress concentrations and ensuring a strong, leak-proof connection. Their long tapered hub makes them ideal for high-pressure and extreme temperature environments.

Weld neck flanges are designed to provide a smooth transition from the pipe to the flange, reducing stress concentrations and ensuring a strong, leak-proof connection. Their long tapered hub makes them ideal for high-pressure and extreme temperature environments.

• Long Weld Neck Flanges:  Similar to weld neck flanges, long weld neck flanges have a longer neck, providing additional strength and support in high-pressure applications. These are typically used in applications where reinforcement is critical, such as in boilers and pressure vessels.

Similar to weld neck flanges, long weld neck flanges have a longer neck, providing additional strength and support in high-pressure applications. These are typically used in applications where reinforcement is critical, such as in boilers and pressure vessels.

• Slip On Flanges (SORF):  Slip on flanges are easy to install as they simply slip over the pipe and are welded on both sides. They are suitable for low-pressure applications and are widely used due to their lower initial cost compared to other types.

Slip on flanges are easy to install as they simply slip over the pipe and are welded on both sides. They are suitable for low-pressure applications and are widely used due to their lower initial cost compared to other types.

• Spectacle Blind Flanges:  Spectacle blind flanges are used to blank off the end of a pipe or to isolate a section of the piping system. This flange type can be easily rotated to either block flow or allow flow, providing flexibility in system maintenance and operation.

Spectacle blind flanges are used to blank off the end of a pipe or to isolate a section of the piping system. This flange type can be easily rotated to either block flow or allow flow, providing flexibility in system maintenance and operation.

• Socket Weld Flanges (SWRF): Socket weld flanges feature a recessed area where the pipe is inserted and welded. They are commonly used in small-diameter piping systems for high-pressure applications, ensuring a strong seal.

Socket weld flanges feature a recessed area where the pipe is inserted and welded. They are commonly used in small-diameter piping systems for high-pressure applications, ensuring a strong seal.

• Blind Flanges (BLRF): Blind flanges are solid discs used to seal off the end of a pipe or to create a dead-end in the piping system. They are typically used in systems that may require future expansion or inspection.

Blind flanges are solid discs used to seal off the end of a pipe or to create a dead-end in the piping system. They are typically used in systems that may require future expansion or inspection.

• Threaded Flanges: Threaded flanges are connected to pipes using threads, eliminating the need for welding. These flanges are typically used in low-pressure applications where welding is not feasible or desired.

Threaded flanges are connected to pipes using threads, eliminating the need for welding. These flanges are typically used in low-pressure applications where welding is not feasible or desired.

• Orifice Flanges:  Orifice flanges are used to mount orifice plates for flow measurement applications. They are designed to provide an easy means of checking the flow rate through a system by measuring differential pressure.

Orifice flanges are used to mount orifice plates for flow measurement applications. They are designed to provide an easy means of checking the flow rate through a system by measuring differential pressure.

• High Hub Blind Flange: High hub blind flanges have a raised hub that provides additional strength and support in high-pressure applications. These flanges are ideal for systems requiring durability and reliability under extreme conditions.

High hub blind flanges have a raised hub that provides additional strength and support in high-pressure applications. These flanges are ideal for systems requiring durability and reliability under extreme conditions.

• Lap Joint Flanges / Loose Flanges:  Lap joint flanges are used in conjunction with backing rings to create a leak-proof connection. They are ideal for applications requiring frequent disassembly and inspection, as they are not welded to the pipe.

Lap joint flanges are used in conjunction with backing rings to create a leak-proof connection. They are ideal for applications requiring frequent disassembly and inspection, as they are not welded to the pipe.

• Square Flanges: Square flanges have a square shape and are commonly used in low-pressure applications. They provide a different geometric alternative where traditional round flanges may not be necessary.

Square flanges have a square shape and are commonly used in low-pressure applications. They provide a different geometric alternative where traditional round flanges may not be necessary.

• Ring Type Joint Flanges: Ring type joint flanges use a metal ring gasket to create a leak-proof seal. These are commonly used in high-pressure and high-temperature applications, ensuring long-term reliability.

Ring type joint flanges use a metal ring gasket to create a leak-proof seal. These are commonly used in high-pressure and high-temperature applications, ensuring long-term reliability.

• Tongue and Groove Flange: Tongue and groove flanges have a tongue-and-groove design that interlocks to create a secure and leak-proof connection. They are ideal for systems requiring precise alignment and sealing.

Tongue and groove flanges have a tongue-and-groove design that interlocks to create a secure and leak-proof connection. They are ideal for systems requiring precise alignment and sealing.

• Expander Flanges:  Expander flanges are designed to expand the pipe to create a tight seal. They are particularly useful in situations where an increase in pipe diameter is required within a limited space.

Expander flanges are designed to expand the pipe to create a tight seal. They are particularly useful in situations where an increase in pipe diameter is required within a limited space.

• Reducing Flanges:  Reducing flanges are used to connect pipes of different diameters. These flanges provide a smooth transition between pipe sizes without the need for additional adapters or reducers.

Reducing flanges are used to connect pipes of different diameters. These flanges provide a smooth transition between pipe sizes without the need for additional adapters or reducers.

• Male Flanges – Female Flanges:  Male flanges have a male threaded end that connects to a female threaded fitting. These are commonly used in systems where threaded connections are preferred over welded ones, allowing for easy assembly and disassembly.

Male flanges have a male threaded end that connects to a female threaded fitting. These are commonly used in systems where threaded connections are preferred over welded ones, allowing for easy assembly and disassembly.

Flange Supplier – All Type of Flange Solutions – Flange Manufacturers – Omaa metal Sources

Why Choose Us?

• Extensive inventory of flange types and sizes

• Custom flange manufacturing capabilities

• Competitive pricing

• Prompt delivery times

• Exceptional customer service

Closing Thoughts:

Choosing the right type of flange is essential for ensuring the safety, reliability, and efficiency of industrial piping systems. Whether your need is for high-pressure applications, flow control, or easy disassembly, our extensive range of flanges ensures you will find the perfect solution for your industrial requirements.

As a leading manufacturer and supplier, we provide flange solutions to countries including Oman, South Africa, Saudi Arabia, Italy, Malaysia, Bahrain, Myanmar, Kuwait, Indonesia, Dubai, United Arab Emirates (UAE), Thailand (Bangkok), Iran, Turkey, Australia, Singapore, Vietnam, Iraq, Qatar, Oman, Kazakhstan, Netherlands, United States, Mexico, China, Brazil, Peru, Nigeria, Jordan, Venezuela, Germany, UK, Canada, Russia, New Zealand, Sri Lanka, Sudan, Israel, Kenya, Morocco, South Korea, Cambodia, Colombia, France, Gabon, Angola, Algeria, Ukraine, and Egypt.