Nickel Alloy Round Bars Manufacturer – Supplier for Muscat, Oman

Nickel Alloy 200 is a versatile and widely used alloy with exceptional corrosion resistance and mechanical strength. Omaaforged is a leading supplier and manufacturer of Nickel Alloy 200 Round Bars in Muscat, Oman. In this comprehensive article, we will delve into the properties, applications, and availability of Nickel Alloy 200 Round Bars in the Muscat region.

Properties of Nickel Alloy 200

- Excellent Corrosion Resistance: Nickel Alloy 200 is highly resistant to corrosion in various environments, including acids, alkalis, and salts.

- High Strength: Despite its low carbon content, Nickel Alloy 200 exhibits high tensile, yield, and fatigue strength.

- Formability: Nickel Alloy 200 is easily formed, making it suitable for bending, welding, and other fabrication processes.

- Non-Magnetic: Nickel Alloy 200 exhibits non-magnetic properties, making it ideal for use in electrical applications.

Applications of Nickel Alloy 200 Round Bars

Nickel Alloy 200 Round Bars are widely used in a diverse range of industries in Muscat, Oman, including:

- Chemical Processing: Tanks, pipes, and vessels for handling corrosive chemicals

- Marine: Propellers, shafts, and rudders in marine environments

- Oil and Gas: Pumps, valves, and piping systems in oil and gas extraction and refining

- Food Processing: Equipment for food processing and storage

- Pharmaceutical: Piping and components for pharmaceutical manufacturing

Availability in Muscat, Oman

Omaa Metal Sources website Omaaforged maintains a comprehensive inventory of Nickel Alloy 200 Round Bars in Muscat, Oman. We offer a wide range of sizes, grades, and specifications to meet the diverse requirements of our customers.

Standards and Certifications

Nickel Alloy 200 Round Bars supplied by Omaaforged meet international standards, including:

- ASTM B160

- UNS N02200

- EN 1.6242 (2.4066)

We also Manufactur and supply all type of flange in Oman, Below is an overview of the most common types of flanges used across industries:

Types of Flanges:

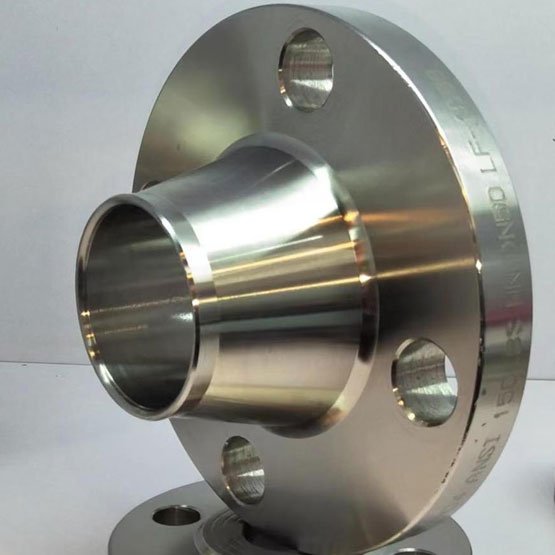

• Weld Neck Flanges (WNRF / WNFF): Weld neck flanges are designed to provide a smooth transition from the pipe to the flange, reducing stress concentrations and ensuring a strong, leak-proof connection. Their long tapered hub makes them ideal for high-pressure and extreme temperature environments.

Weld neck flanges are designed to provide a smooth transition from the pipe to the flange, reducing stress concentrations and ensuring a strong, leak-proof connection. Their long tapered hub makes them ideal for high-pressure and extreme temperature environments.

• Long Weld Neck Flanges:  Similar to weld neck flanges, long weld neck flanges have a longer neck, providing additional strength and support in high-pressure applications. These are typically used in applications where reinforcement is critical, such as in boilers and pressure vessels.

Similar to weld neck flanges, long weld neck flanges have a longer neck, providing additional strength and support in high-pressure applications. These are typically used in applications where reinforcement is critical, such as in boilers and pressure vessels.

• Slip On Flanges (SORF):  Slip on flanges are easy to install as they simply slip over the pipe and are welded on both sides. They are suitable for low-pressure applications and are widely used due to their lower initial cost compared to other types.

Slip on flanges are easy to install as they simply slip over the pipe and are welded on both sides. They are suitable for low-pressure applications and are widely used due to their lower initial cost compared to other types.

• Spectacle Blind Flanges:  Spectacle blind flanges are used to blank off the end of a pipe or to isolate a section of the piping system. This flange type can be easily rotated to either block flow or allow flow, providing flexibility in system maintenance and operation.

Spectacle blind flanges are used to blank off the end of a pipe or to isolate a section of the piping system. This flange type can be easily rotated to either block flow or allow flow, providing flexibility in system maintenance and operation.

• Socket Weld Flanges (SWRF): Socket weld flanges feature a recessed area where the pipe is inserted and welded. They are commonly used in small-diameter piping systems for high-pressure applications, ensuring a strong seal.

Socket weld flanges feature a recessed area where the pipe is inserted and welded. They are commonly used in small-diameter piping systems for high-pressure applications, ensuring a strong seal.

• Blind Flanges (BLRF): Blind flanges are solid discs used to seal off the end of a pipe or to create a dead-end in the piping system. They are typically used in systems that may require future expansion or inspection.

Blind flanges are solid discs used to seal off the end of a pipe or to create a dead-end in the piping system. They are typically used in systems that may require future expansion or inspection.

• Threaded Flanges: Threaded flanges are connected to pipes using threads, eliminating the need for welding. These flanges are typically used in low-pressure applications where welding is not feasible or desired.

Threaded flanges are connected to pipes using threads, eliminating the need for welding. These flanges are typically used in low-pressure applications where welding is not feasible or desired.

• Orifice Flanges:  Orifice flanges are used to mount orifice plates for flow measurement applications. They are designed to provide an easy means of checking the flow rate through a system by measuring differential pressure.

Orifice flanges are used to mount orifice plates for flow measurement applications. They are designed to provide an easy means of checking the flow rate through a system by measuring differential pressure.

• High Hub Blind Flange: High hub blind flanges have a raised hub that provides additional strength and support in high-pressure applications. These flanges are ideal for systems requiring durability and reliability under extreme conditions.

High hub blind flanges have a raised hub that provides additional strength and support in high-pressure applications. These flanges are ideal for systems requiring durability and reliability under extreme conditions.

• Lap Joint Flanges / Loose Flanges:  Lap joint flanges are used in conjunction with backing rings to create a leak-proof connection. They are ideal for applications requiring frequent disassembly and inspection, as they are not welded to the pipe.

Lap joint flanges are used in conjunction with backing rings to create a leak-proof connection. They are ideal for applications requiring frequent disassembly and inspection, as they are not welded to the pipe.

• Square Flanges: Square flanges have a square shape and are commonly used in low-pressure applications. They provide a different geometric alternative where traditional round flanges may not be necessary.

Square flanges have a square shape and are commonly used in low-pressure applications. They provide a different geometric alternative where traditional round flanges may not be necessary.

• Ring Type Joint Flanges: Ring type joint flanges use a metal ring gasket to create a leak-proof seal. These are commonly used in high-pressure and high-temperature applications, ensuring long-term reliability.

Ring type joint flanges use a metal ring gasket to create a leak-proof seal. These are commonly used in high-pressure and high-temperature applications, ensuring long-term reliability.

• Tongue and Groove Flange: Tongue and groove flanges have a tongue-and-groove design that interlocks to create a secure and leak-proof connection. They are ideal for systems requiring precise alignment and sealing.

Tongue and groove flanges have a tongue-and-groove design that interlocks to create a secure and leak-proof connection. They are ideal for systems requiring precise alignment and sealing.

• Expander Flanges:  Expander flanges are designed to expand the pipe to create a tight seal. They are particularly useful in situations where an increase in pipe diameter is required within a limited space.

Expander flanges are designed to expand the pipe to create a tight seal. They are particularly useful in situations where an increase in pipe diameter is required within a limited space.

• Reducing Flanges:  Reducing flanges are used to connect pipes of different diameters. These flanges provide a smooth transition between pipe sizes without the need for additional adapters or reducers.

Reducing flanges are used to connect pipes of different diameters. These flanges provide a smooth transition between pipe sizes without the need for additional adapters or reducers.

• Male Flanges – Female Flanges:  Male flanges have a male threaded end that connects to a female threaded fitting. These are commonly used in systems where threaded connections are preferred over welded ones, allowing for easy assembly and disassembly.

Male flanges have a male threaded end that connects to a female threaded fitting. These are commonly used in systems where threaded connections are preferred over welded ones, allowing for easy assembly and disassembly.

Contact Us Today

For more information about Nickel Alloy 200 Round Bars or to place an order, contact us today. Our experienced team is ready to assist you with any inquiries you may have.

About Omaa Metal Sources

Omaa Metal Sources is a leading supplier of Nickel Alloy 200 Round Bars in Muscat, Oman. We are committed to providing high-quality products, exceptional customer service, and competitive pricing. Our extensive inventory and prompt delivery times ensure timely fulfillment of your orders.